Welcome to Kantrola

Zero-defect manufacturing with AI and IoT 500x faster.

Overview

Automating assembly line quality control

Kantrola automates assembly line quality control with real-time defect detection, comprehensive metrics monitoring, and seamless data access for root cause analysis, ensuring efficient and error-free production.

-

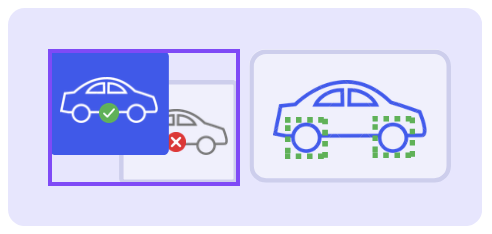

No Code

- Train models with a simple point & click interface

-

Detect anomalies

- Detect defects, missing components, & wrong versioned components

-

Monitor

- Real-time alerts, dispute results, track components, & view analytics

-

Short timelines

- To production in 50 minutes.

How it works

1

Setup

Place camera & edge device on the assembly line.

2

Gather Data

Collect images of correct and defective components.

3

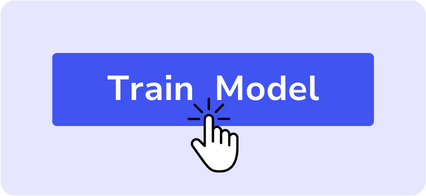

Train

Train your ML model with the click of a button.

4

Evaluate & Deploy

Evaluate model & deploy to the smart edge device.

Get started now

See how Kantrola can help you achieve zero-defective manufacturing in minutes, not months.